Duraslate | For Electrical Appliances

What Is Matrix Technology?

Matrix technology is a process of internally reinforcing a multi-coat nonstick coating with specially engineered particles that form an actual structural "matrix" between the first and second layers. This matrix prevents the coating layers from separating, even when under heavy stress (like being scraped by a metal spatula.)

Matrix technology is the most advanced coating reinforcement process, and was invented by GMM. The below videos show "typical" reinforced coatings on irons and grills versus the DURASLATE® technology.

Irons: Very Low Friction Needed

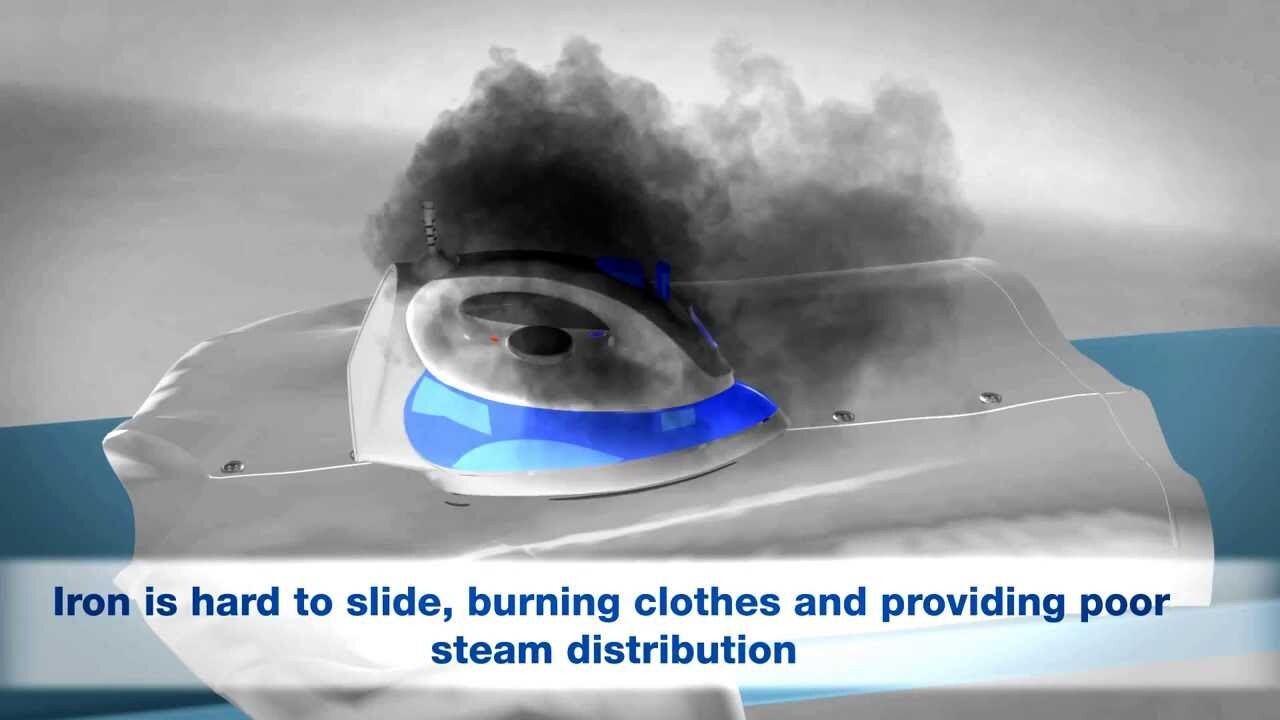

The Problem - Electric Irons

“Standard” Internally Reinforced two coat non-stick systems for irons are composed of a primer and topcoat. However, no internal structure “binds” these 2 individual layers together. Therefore, it is still easy to “wear off” the topcoat layer through normal ironing, which results in a drastic decrease in low friction properties. Click on the video clip for a visual example of this "layering" problem on an electric iron.

Enter Duraslate® - Matrix Technology for Irons

DURASLATE® has a special interlocking matrix of reinforcements that "binds" the primer and topcoat together, resulting in a far higher degree of durability and release properties. Click on the video clip to see how GMM's proprietary matrix technology binds the primer and topcoat together on an electric iron.

Corrosion: The Problem On Electric Grills

The Dishwasher: A Huge Problem for Grills

A significant problem faced by electrical grill manufacturers is that nonstick coatings can corrode over time in the dishwasher—salty water and acidic spices can be extremely (and surprisingly) caustic. Click on the video to see how a "typical" reinforced nonstick coating corrodes, resulting in blistering and poor food release.

Enter Duraslate – Fantastic Corrosion Resistance

GMM has designed DURASLATE® to be especially resistant to corrosion in the kitchen environment. This resistance is provided by the interlocking matrix of reinforcements that prevent fluids from getting underneath the coating surface. Click on the video for a demonstration of this effect.